How Shanti Polymers Packaging Solutions EPE Foam Products Is Ideal Cushioning Material?

In the realm of packaging solutions, the choice of cushioning material plays a pivotal role in ensuring the safety and integrity of goods during transit. Among the myriad options available, Expanded Polyethylene (EPE) stands out as an ideal cushioning material, offering a combination of versatility, durability, and eco-friendliness. In this article, we delve into the world of EPE packaging solutions offered by Shanti Polymers and explore why they are the perfect choice for cushioning applications.

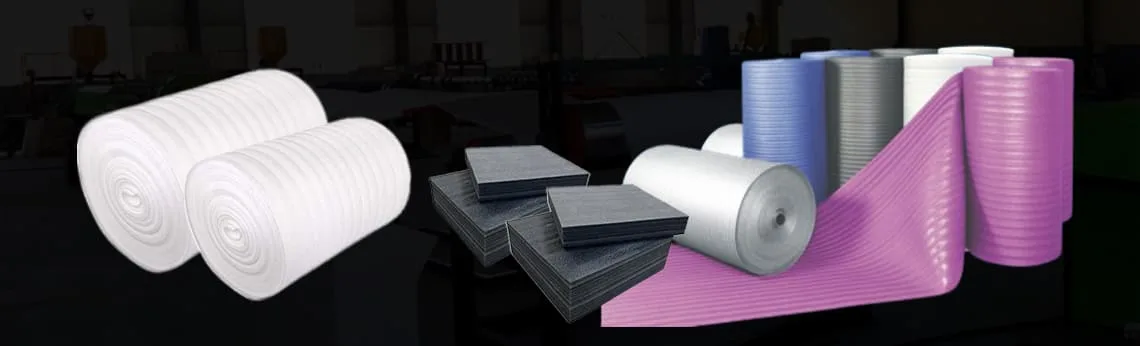

EPE, also known as foam or pearl foam, is a lightweight and resilient material renowned for its cushioning properties. As a key component in packaging solutions, EPE foam rolls and bags are utilized to protect fragile items from damage during shipping and handling. The ability of EPE to absorb shocks and vibrations makes it an indispensable material for safeguarding goods across various industries.

Advantages of EPE Foam Rolls and Bags

One of the primary advantages of EPE packaging materials is their lightweight nature, which reduces shipping costs and minimizes environmental impact. Despite being lightweight, EPE foam exhibits excellent cushioning properties, effectively absorbing impacts and preventing damage to packaged items. Additionally, EPE is highly flexible, allowing for easy customization to fit the contours of different products.

Also Read:[Why Packaging Quality Matters: Insights from Shanti Polymers.]

Shanti Polymers: Leading Provider of EPE Packaging Solutions

Shanti Polymers emerges as a trusted name in the realm of packaging solutions, offering a wide range of EPE materials tailored to meet diverse needs. With a focus on innovation and quality, Shanti Polymers provides EPE foam rolls, bags, and other packaging materials designed to ensure the safety and security of goods in transit. Moreover, the company’s commitment to environmentally-friendly materials aligns with the growing demand for sustainable packaging solutions.

Applications of EPE Packaging Materials

EPE packaging materials find applications across various industries, including electronics, pharmaceuticals, automotive, and consumer goods. Whether it’s protecting delicate electronic components, insulating temperature-sensitive pharmaceuticals, or cushioning automotive parts, EPE foam rolls and bags offer versatile solutions for packaging challenges.

Sustainability of EPE Packaging

In an era marked by increasing environmental awareness, sustainability has become a key consideration in packaging decisions. EPE foam stands out as an eco-friendly option, as it is recyclable and can be reused multiple times without compromising its cushioning properties. By opting for EPE packaging materials, businesses can reduce their carbon footprint and contribute to a greener future.

Customization Options for EPE Packaging

One of the standout features of EPE packaging solutions is their versatility and customizability. Shanti Polymers offers a range of customization options, allowing businesses to tailor packaging solutions to their specific requirements. From custom sizes and shapes to branded printing and inserts, EPE foam rolls and bags can be customized to enhance product presentation and brand visibility.

EPE Roll and Sheet Bag Manufacturers

When sourcing EPE packaging materials, partnering with reputable manufacturers and suppliers is essential to ensure product quality and reliability. Shanti Polymers, as a leading manufacturer of EPE rolls and sheet bags, adheres to stringent quality standards and offers dependable solutions for packaging needs. By collaborating with trusted suppliers, businesses can rest assured that their packaging requirements are met with professionalism and excellence.

Lightweight EPE Packaging: Benefits and Applications

The lightweight nature of EPE packaging materials offers several benefits, particularly in industries reliant on efficient logistics and transportation. By reducing the overall weight of packaged goods, businesses can lower shipping costs and improve operational efficiency. Moreover, lightweight EPE packaging is well-suited for e-commerce applications, where minimizing package weight can lead to significant savings in shipping expenses.

Conclusion

In conclusion, Shanti Polymers’ EPE packaging solutions emerge as the ideal choice for cushioning applications, offering unmatched versatility, durability, and sustainability. With a commitment to quality and innovation, Shanti Polymers provides businesses across industries with reliable packaging materials designed to protect and showcase their products. By leveraging the benefits of EPE foam rolls and bags, businesses can enhance their packaging efficiency while reducing environmental impact.