5 Reasons Why PP Corrugated Box Packaging Is Better Than Wooden Crate Packaging

The effectiveness of shipping goods depends majorly on the packaging, making it a crucial aspect of logistics. Over the years, various materials have been used for packaging purposes, with wooden crates gaining the most traction. However, with the rise in technology and the flaws in traditional packaging, PP corrugated boxes rapidly started to replace wooden crates as the preferred packaging solution. In this blog, we will explore 5 reasons why PP corrugated box packaging is better than wooden crate packaging.

PP Corrugated Box Packaging is Lightweight & Convenient

First and foremost, PP corrugated box packaging is lightweight and extremely easy to handle in comparison to wooden crate packaging. This lightweight property helps drastically reduce the overall shipping weight and also allows easier loading-unloading as well as transportation. PP corrugated box packaging is also cost-effective in terms of reduced shipping charges.

PP Corrugated Box Packaging Offers Superior Protection

Another aspect where PP corrugated box packaging surpasses wooden crate packing is its superiority in goods protection. As the name suggests, PP boxes are manufactured using Polypropylene, an inherently durable and flexible material with excellent impact resistance. Additionally, the corrugated structure offers cushioning and absorbs shocks during transit, alleviating the risk of damage to the goods.

On the other hand, wooden crates may be susceptible to splintering or breaking under heavy loads, potentially compromising safety standards.

PP Corrugated Box Packaging Is Moisture Resistance

One major flaw of wooden crate packaging is its low resistance to the adverse effects of moisture. This can lead to swelling, warping, or mold growth.

In contrast, PP corrugated boxes are highly moisture resistant thanks to Polypropylene. The material does not absorb moisture, making it highly desirable for packaging in humid or wet conditions. More importantly, PP corrugated box packaging is ideal for goods that are sensitive to moisture like electronics, pharmaceuticals, or edibles.

PP Corrugated Box Packaging is Eco-Friendly

In this day and age, where sustainability is more important than ever, eco-friendly packaging solutions have become a necessity. As such, PP corrugated box packaging is highly sought-after by environmentally conscious businesses. Polypropylene, the raw material used in PP boxes is recyclable. Additionally, these units can easily be broken down and recycled into new products. In essence, PP corrugated box packaging reduces the environmental impact by promoting a circular economy.

Wooden crates, on the other hand, are made from timber resources that are not as easily recyclable.

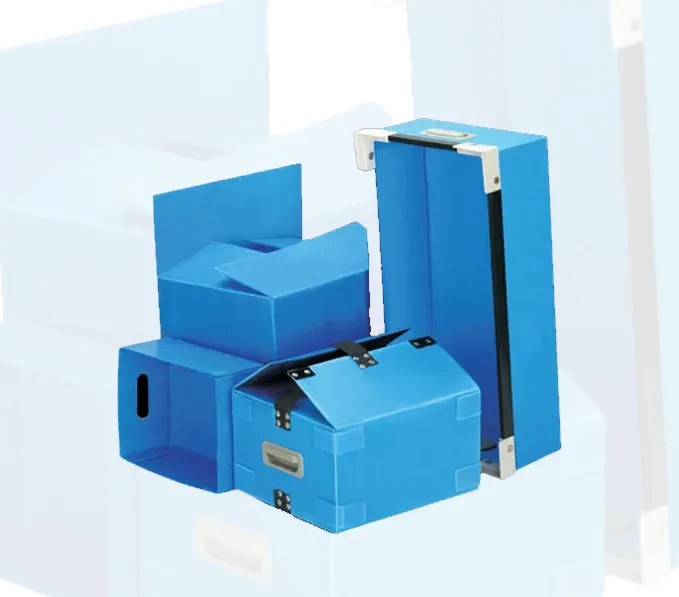

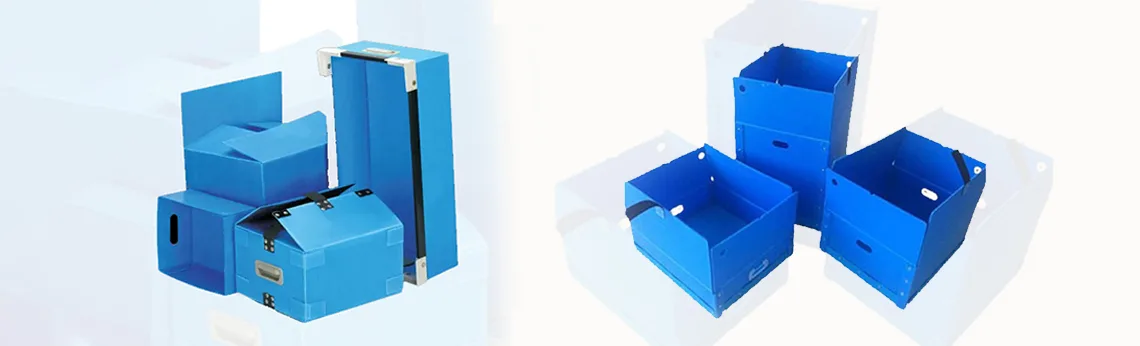

PP Corrugated Box Packaging Can Be Customized

PP corrugated packaging is highly flexible in terms of customization and branding options. The smooth surface of these boxes allows for easy printing of logos, labels, and product information to create packaging that promotes consistent branding. Moreover, PP boxes can be cut, folded, or formed into a variety of shapes and sizes to lodge different kinds of products.

In A Nutshell

PP corrugated box packaging proves to be better than wooden crate packaging in almost every logistical aspect. It is lightweight, exceptionally protective, moisture resistant, eco-friendly, and customizable. With its commitment to quality standards and customer satisfaction, Shanti Polymers has emerged as the smart packaging partner for businesses across various industries. The brand also promises a greener packaging solution with sustainable manufacturing processes.